Changes in the vehicle parc and the challenges of intellectual property have created issues for turbocharger reman. Whatever happens, argues Martyn Howorth, this part of the aftermarket must avoid a ‘race to the bottom’

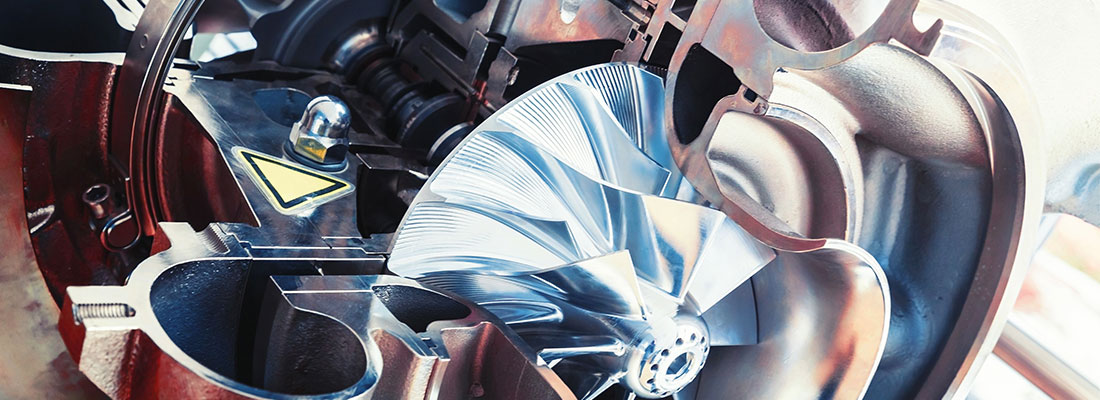

Turbocharging, one of the key technologies for improving the efficiency of petrol engines, is under scrutiny. Martyn Howorth, sales director at UK reman specialist Melett, has been in the turbocharger industry all his working life and has an interesting perspective on the various trends in Europe’s turbocharger aftermarket. Speaking at ReMaTec 2017 in Amsterdam, he pointed out that there has been a lot of negative press about whether diesel engines are dead, with talk about eliminating their use in major urban areas such as London, Madrid, Paris and Mexico City. This seems to create a question mark: if diesels are under threat, then so are turbochargers? “Actually, no,” Howorth says. “Car manufacturers have been aware that there is an increasing cost and complexity to make diesel engines compliant with emissions regulations. So they’ve been moving away from them for some time and focusing on developing gasoline engines with things that you already see out there such as variable valve timing, improved fuel injection, cylinder de-activation, downsizing – and, of course, turbochargers.”

Life is still good

Looking at it this way, he argues, while the Volkswagen ‘Dieselgate’ scandal has contributed to the problem, diesel was predicted to fall anyway - from 53% penetration in Europe now to under 35% by 2020). “That’s the bad news,” he says. “The good news is that most diesel engines will be replaced by gasoline engines and a lot of those will be turbocharged. Life is still good – we estimate that aftermarket volumes will continue to grow.” Indeed, he cited figures showing that the OEM market will increase 40% between now and 2022: 43% of light vehicles now are turboed and that is forecast to reach 63% over the next ten years. “Even hybrid engines are predicted to be turbocharged in most cases,” Howorth went on. “The volume of turbos for gasoline engines is going to increase but we think gasoline turbos will fail sooner than the diesel variants - primarily because of higher exhaust gas temperatures. So those of us involved in the turbo business can rest easy – it will continue to give us growth in the aftermarket.”

Garage resistance

However, that is not to say that everything in the garden is rosy. Melett carried out some research with UK garages to see what they thought about remanufactured product. About half of those surveyed were buying from a local turbo specialist, and the other half sourced their product from multifactors or OEM dealers. “A significant amount of garages didn’t want reman – they wanted new,” Howorth explains. “And they didn’t use the word ‘reman’, they said ‘used’ or ‘second hand’. So why should there be such resistance by garages to the idea of reman turbochargers? Howorth explained that some of them differentiated between vehicles based on the age profile and quality, e.g. a 2012 BMW 535 still has a very high residual value and customer is prepared to pay a little bit more. However, the owner of a ten-year old Peugeot 206 which has already gone through two turbos is not likely to want to pay very much money for a repair solution – therefore will probably pay for reman rather than new. What vehicles were used for had an important impact on repair too: for instance, owners of working vehicles - such as taxis or ‘white vans’ - will tend to pay more for a repair solution because they earn a living from it. There are specific physical considerations as well – not least over how easy it is for the garage to get the turbo out and back in. Howorth cited the example of a Mercedes 300E diesel 2009: the turbo is sat between the ‘V’ of the engine and thus takes technicians two or three hours to get it out and get it in “so there’s not too much risk for the garage”. At the other end of the spectrum, Land Rover Discovery and Range Rover models around 2008-09 are a “nightmare”. "You’ve got to take the body off to get at the turbocharger – it can take a day to two days of labour,” Howorth suggested. This means that Land Rover specialists said they would only use new because the risk of it not being right first time is too great.

Variation in quality

“The other thing we found was the variation in quality: you get the good, the bad and the ugly in turbocharger workshops,” he explains. “So the garages’ attitude to reman will depend on the quality of the last workshop they used.” A further interesting issue thrown up by the research is the sheer breadth of product which is now available. “In 2010 they could buy a new OE turbo at top price, in the middle a reman turbo or even repaired turbos. In 2017 the range is wider: OE, remanufactured OEM turbos from Garrett or BorgWarner, an aftermarket new turbo, reman or repaired. So there is a lot more option out there.” Melett’s sense from all this is that, if someone had used poor quality parts and service, the garage is more reluctant to use reman. “If they conduct a poor repair, the whole industry is damaged,” he warns. Meanwhile, few European countries have experienced booming new car registrations between 2005 and 2015 – and this is having an impact on turbo reman as well, he continued.

Prices driven down

Germany has not had much in the way of growth – but other countries have experienced far worse. In Italy, registrations went down from 2007 and are barely recovering now, while Spain has seen the most dramatic impact, with volumes which have halved since 2007 and never recovered. For remanufacturers, this is a problem. The reman sweet spot for applications is between five and seven years – this is where the industry sells the most product, Howorth said – but that generation of vehicles is missing in Spain and Italy, and perhaps in Greece and Portugal as well. “Spain is where we’re seeing prices driven down and down and down,” he explained. “But what happens in Spain doesn’t stay in Spain because we live in a connected world. So we’re observing the knife fight to get the business of these older applications as the average age increases: it means prices are being driven down viciously on the old applications in some markets and that’s having an impact on other markets – worse still, it’s also affecting the price of reman turbos in newer applications because people say: ‘Okay, you’re going to charge me 200 euros for this old Peugeot 1.6 HDI turbo – and it’s very similar in size to this turbo which goes on a four-year old BMW 120 – why should I pay more?’ And that is driving the price and quality equation down – and that’s of concern to us.” This is not the only challenge for remanufacturers.

Increasing complexity

Turning to the newer generation of turbochargers, he said they are becoming – because of emissions legislation – more and more complex, with a greater variety of models. He cites a BMW four-litre application, with fabricated turbine housings and complex outlets. “There’s not enough volume out there for a manufacturer to invest in the tooling to make the whole range,” he says. “So nobody could possibly make this full range of turbos which means potentially it is left in the hands of an OEM monopoly which is just not good.” OEMs might see things differently, but the point about the increasing intricacy – and the independent aftermarket’s difficulties in finding a way through the morass of intellectual property – is one that many will recognise. Actuation systems are just one element which have become more sophisticated, more complex, more integrated into the engine management system, Howorth says. Melett has “had to invest a lot of money to design a way around it to offer a solution for the market”. “What worries me is that we end up with a monopoly on new turbos from the OEM and a reman industry that’s driven itself into the ground through pricing, through lower quality parts and damaged its reputation – and so then where are we?” he asks. “It’s a difficult situation. So we need to ensure that turbocharger reman remains viable, remains sustainable into the future. We need to avoid that ‘race to the bottom’ on price.” He knows that is easy to say – less easy to carry out when garages face price pressure from customers looking for the best deal.

Courage and sustainability

Howorth is honest enough to admit that he does not have a cast iron solution for these problems. “I won’t pretend to have a monopoly on wisdom and I think this issue raises more questions than it gives us answers,” he concludes. “We’d like to see that quality reman space for vehicles in the three- to ten-year zone remain. Obviously, you’ve got OEM new turbos in the warranty period in the early life cycle. We’d like to see that flourishing quality reman segment. And then for the older stuff, the very old vehicles, then of course there’s always going to be the cheap and cheerful reman and repair solutions – but we need to try and compartmentalise it into that zone.” That being the case, what does he think that the turbo reman sector should be doing? “We need as businesses to have the courage to maintain our quality standards, our margins, to ensure that we have sustainable businesses into the future,” he insists. “Education is everything: Melett is very strong on putting out that message into the market, promoting quality remanufacturing to garages, with our ‘What’s in your turbo?’ campaign which has been going on for quite some time. But who else is going to do this? The multifactors? I don’t think so. Suppliers? Some will, some won’t. And the turbo specialists? We’re looking to keep the quality high.”