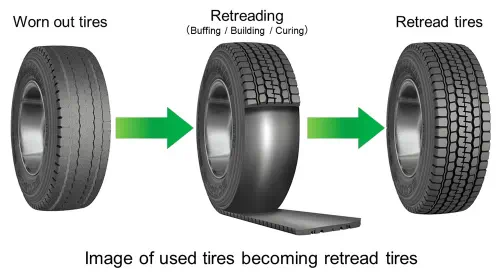

Retread tyres are more affordable than new tyres, which has led to an increase in their sales. Retread tyres are also environmentally friendly, which has helped the business grow overall because consumers are more likely to choose sustainable options. As a result, a growing number of manufacturers have begun putting retread tyres on both commercial and heavy-duty vehicles. Under the tread, tyre casings often still have a long lifespan. Before switching out the worn tyre treads for newly vulcanized ones, these casings must first undergo a rigorous inspection and repair process known as retreading. Unique tread designs can withstand the challenges of your business.

Retread tyres as a smart eco-friendly and economic opportunity

Retread tyres are significantly more environmentally friendly than new tyres because they produce fewer carbon emissions during the retreading process than a new tyre would. Therefore, it is thought that the procedure is more fuel-efficient. This procedure involves replacing the worn-out tread coating with a new layer on top of a high-quality casing. Because it uses a smaller number of raw materials than is needed to make a new tyre, the technique is therefore viewed as being more environmentally friendly. Retreading tyres helps to cut down on tyre landfilling and scrapping. This not only assists businesses in reducing production costs, but it also provides overall improved environmental advantages.

Modern technology opens a wide market

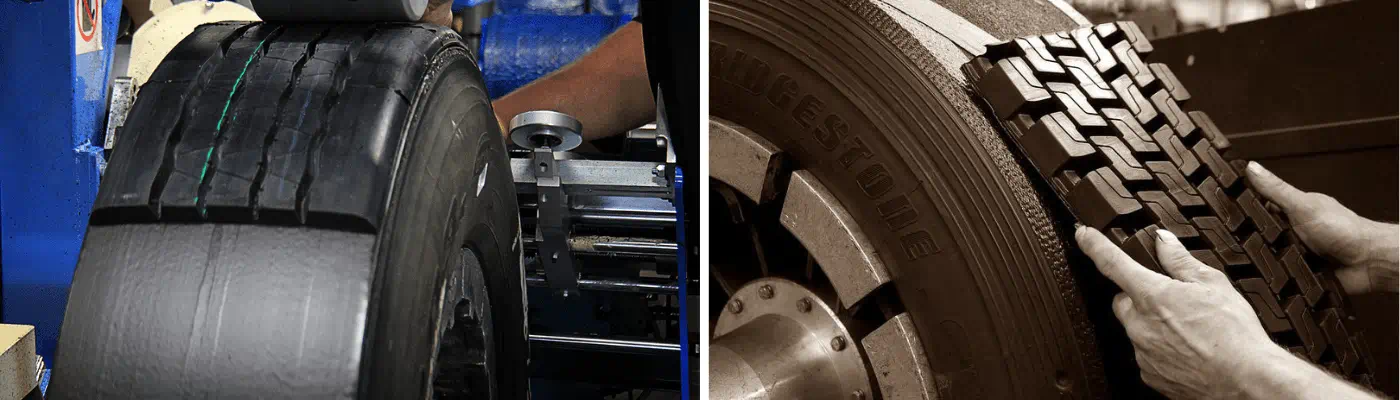

Retread tyres are now safer and more efficient than ever thanks to ongoing advancements in retread tools, procedures, and production techniques. Today's premium radial tyres are created with the possibility of retreading in mind. Fresh tread can be applied to intact casings in good condition at least once, and frequently numerous times. Simply put, the procedure entails stripping out worn-out tread pieces, mending any damage, resurfacing the tyre, and then applying a brand-new layer of tread to the casing.

Retreading is such a successful method of managing truck and fleet tyres that, for instance, retreads make up over half of all replacement truck tyres in North America. Commercial tyres can start over and withstand all the same challenges as new tyres thanks to cutting-edge retread processes and tread patterns. Commercial fleet operators are seeking for solutions to cut fuel use as a result of the burdensome rules placed upon them. Therefore, environmental consciousness is leading the charge for reform in the car industry. Retread tyre sales will increase as a result in the upcoming years. Both independent service providers and original equipment manufacturers offer retread tyres. Independent service providers have cemented their dominance as the preferred sales channel in the market by finding that major vehicle fleet owners prefer to purchase retread tyres from them. A favourable climate for the sales of retread tyres has been generated by the expansion of the logistics sector and the increased need for freight transportation. The need for tyre retreading has grown as a result of the increased wear and tear on tyres. Fleet managers are seeking for ways to save expenses while keeping their fleet of vehicles safe and environmentally friendly. Retread tyres have been used by fleet owners to combat this issue, and many people are finding them to be helpful.

A new vision of green economy

The retread tyre becomes one of the key references for attaining the challenging sustainability targets that Europe has set for itself as part of the new vision it seeks for the green economy. Countries like France currently require public transportation fleets to regularly assess the use of retread tyres in this approach, and many other European nations are preparing themselves in a similar manner. Commercial retread tyres, as we've already seen, have the same appearance and functionality as brand-new tyres, but at a much-reduced price, with added advantages for the economy, the environment, and efficiency. The financial reduction for your fleet may be the most significant of the many advantages of retread tyres. A retread strategy can enhance your fleet's metrics like cost-per-kilometre, cost-per-load, and cost-per-vehicle, among others, according to a report from Robert Handfield, Ph.D. at North Carolina State University.

Simply replacing the tread that touches the road only accounts for a minor portion of the cost of a new tyre because the majority of the cost of new tyres is incurred by the tyre casing. Retread tyres cost between 30 and 50 percent less than equivalent new tyres while retaining about 90% of the tyres' "absolutely acceptable material." You can cut the price of a tyre by half to two-thirds between the immediate cost reduction and the life extension by retreading it once or more.

The advantages of retread tyres

Tyres usually end up in landfills once they have served their purpose. However, the retread procedure helps tyre rubber last longer and avoids landfills for a longer period of time. Each retread tyre consumes around 60 fewer litres of oil and 30% less energy to produce than a new tyre, according to the NHTSA Commercial Medium Tyre Debris Study. Accordingly, the average retread tyre requires only 28 litres of oil to make, compared to up to 83 litres for a brand-new tyre. An annual average of almost 90,000 tons of truck tyre rubber can be polished by a tyre retread. Rubber may be recycled and given new life as rubber mulch, rubber mats, and playground surfaces, among other things. Retread tyres last as long as brand-new tyres, if not longer. The technique is better than ever. They function just like brand-new tyres but cost a fraction of the price. With the right care, quality retread work can increase your tyres' mileage to levels comparable to those of most brand-new tyres. According to some estimations, a retread can extend the life of your tyres by more than 800,000 kilometers when combined with regular preventive maintenance procedures and adequate inflation to prevent heat build-up.