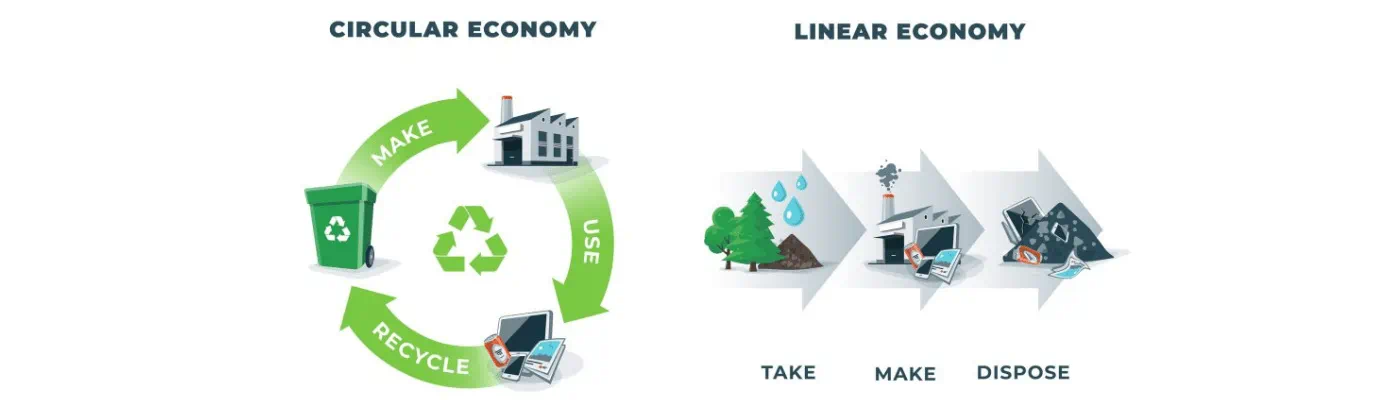

Industry rethinking is being prompted by resource scarcity and climate policy. It is no longer possible to comply with the strict EU requirements using the linear economy that has previously been dominant. The circular economy, recycling, and remanufacturing are the main areas of concentration in addition to the production, use, and disposal of materials. The implementation of the circular economy is difficult, though, because there are so many producers and consumers. Information on the many lifecycles is frequently only locally accessible, making it impossible to assess reuse, recycling, or remanufacturing.

How the new open data ecosystem can help the remanufacturing

The mission of Catena-X

The automotive sector is actively undergoing change. Combustion engines are replaced with electric motors. Resources can be recycled thanks to the circular economy. At the same time, digitalization opens up entirely new possibilities for meeting customer demands, improving the environmental friendliness of production methods, and overall escalating competition. Geopolitical conflicts, pandemics, and climate change all have a significant impact on the automotive industry's necessary transformation.

Today, no corporation can successfully navigate any of these difficulties on its own. Throughout the entire supply chain, material flows should be digitally traceable, and lawmakers will soon demand transparency. Consequently, Catena-X's goal is to make digital information flow across the whole supply chain possible. In the automotive business, many suppliers are highly unsure about the additional value of sharing their data and place a very high risk of data loss or the unfavourable effects of so-called lock-in effects. As a result, the appropriate technology, incentive systems, and business models are lacking. Therefore, the goal of Catena-X is to link the complete supply chain of automotive manufacturers, remanufacturers, suppliers, and service providers.

In this scenario, the remanufacturing industry has been adapting to technological advancements by updating its know-how and utilizing the most recent instruments available on the market, like Catena-X. So, automotive companies, choosing a secure, reliable, open, and collaborative data environment called Catena-X, will use a sustainable solution for the digitalization of supply chains, particularly for medium-sized and small businesses, provided by the networked nature of end-to-end value chains, in which all partners are on an equal footing, have sovereign control over their data, and are free from lock-in effects. This encourages cooperation and collaboration between market participants and rivals.

.png?h=858&iar=0&w=980&rev=2075602b06e0456faabc80735c65a2c7&extension=,webp&hash=D633475E9D09375CA2966C5F6EC3F1D3)

The integral carbon footprint may be calculated, and traceability can be offered in line with the Supply Chain Act thanks to end-to-end digital documentation. Standardized data exchange and the availability of cross-company applications provide long-term investment security and increase the competitiveness of all businesses, from SMEs to major corporations. Catena-X is a collaborative project that can only be successful with the involvement of numerous stakeholders. The objective is to create a network that is active worldwide. Users and suppliers come together, as do SMEs and Fortune 500 corporations, resource providers and remanufacturers, and so on. All businesses can create new value, especially through the utilization and exploitation of data across organizations. In the supply chain, new business models are developed in this way.

Catena-X, a smart and new opportunity for Remanufacturing

The new open and cooperative data ecosystem CATENA-X can aid the remanufacturing sector in several ways. CATENA-X increases visibility by enabling better component, material, and product tracking and tracing throughout the entire value chain, assisting remanufacturers in determining the origin of components and materials, tracking their usage history, and guaranteeing compliance with quality and safety standards. The data on CATENA-X can be used by remanufacturers to streamline their processes and cut waste. They can track their supply chain using real-time data, spot bottlenecks, and streamline their operations. This may result in more profitability, lower costs, and better productivity. As was previously demonstrated, CATENA-X establishes a platform for communication between various participants in the value chain, such as producers, suppliers, and remanufacturers.

This collaboration may result in increased knowledge exchange, better teamwork, and enhanced communication. The knowledge and experience of other participants in the value chain can be used by remanufacturers to provide better goods and services. Remanufacturers may provide their clients with better goods and services by utilizing CATENA-X. Improved quality and safety standards may result from the value chain's increased traceability and transparency, which may encourage repeat business from customers. Finally, CATENA-X assists the remanufacturing sector in several ways. Remanufacturers can enhance their operations, cut waste, work with other participants in the value chain, and offer better goods and services to their clients by utilizing the data offered by this platform.

The European scenario

The European automotive industry, the world of remanufacturing, is believing more and more in Catena-X, supported by the German brands Volkswagen, BMW, Mercedes, Bosch, ZF, and Schaeffler. The game at stake is that of the supply chains, closely linked to the component supply system which has been in crisis in recent months due to the shortage of semiconductors. In Italy, for example, Confindustria and Anfia are reportedly working to raise awareness among Italian companies and give them reasons to join Catena-X, which has already been joined by Brembo, a worldwide leader in the production of high-tech braking systems. This transformation involves large European subcontracting, with Italian, German, and French industries leading the list. The Germans, for example, know the importance of the Made in Italy supply chain and have understood that they also need Italy. Germany is currently among the top markets for European component manufacturers: in 2019, for example, in Italy alone, they exported around 5 billion, equal to more than 20% of total exports. These are in particular mechanical components, while engines are worth half a billion.

Share your story

Share your remanufacturing stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the remanufacturing industry? The Rematec website and social media channels are a great platform to showcase your stories!

Please contact our Brand Marketing Manager.

Are you an Rematec exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.