The pandemic, the Russian invasion of Ukraine, and soaring energy prices and raw materials intensified the automotive crisis. After the long delivery times for new cars and the limited supply of used vehicles, automotive is now experiencing a shortage of spare parts. This phenomenon is partially explained by a decrease in production during the health crisis, the war in Ukraine, and the switch to delivery by sea rather than by air for parts from China, which considerably lengthens lead times. To face this crisis, remanufacturing can be considered as a statement, more than just a part of the automotive industry. It is a wise future-thinking working process to keep a vehicle running without causing unnecessary waste or wasting valuable resources.

Remanufacturing as a winning card for the circular economy

Remanufacturing can be also considered a winning card in the field of the circular economy. But firstly, what does circular economy mean? The circular economy is a production and consumption model involving sharing, leasing, reusing, remanufacturing, refurbishing, and recycling existing materials and products if possible. In this way, the life cycle of products is extended. In practice, it implies reducing waste to a minimum. The circular economy helps to save energy and reduce the climate impact of manufacturing new products creating value from the used materials that would otherwise be landfilled.

Economic growth and rising levels of consumption in developing and developed countries have been observed as being deeply coupled with natural resource usage and material consumption. The increasing need for natural resources has raised concerns regarding issues such as resource scarcity, undesirable environmental impacts due to material extraction, primary production, suboptimal product disposal, and social or political tensions. Product End-of-Life (EoL) options, such as reusing or recycling, attempt to limit or reduce the amount of waste sent to a landfill, providing strategic means to decouple the link between economic growth and resource usage. These EoL options have the potential to close material loops, further utilize wastes as resources, reducing environmental impacts, conserving natural resources, reducing material prices, and providing job opportunities in developing countries. Remanufacturing, on the other hand, is a unique EoL option due to increasing the number of life cycles of a product before final disposal.

• First, recurring environmental benefits, such as emission and raw material extraction avoidance are obtained with each additional product life cycle.

• Second, individual resource efficiency yields increase through product remanufacture. Resource efficiency or, using more with less will continue to compound with each additional life cycle.

• Third, recirculating products decrease the demand and dependency on primary resource production, further closing the material loop and creating a more circular economy. In addition, remanufacturing can initiate preferable EoL options such as recovery, recycling, and waste reduction.

The history of remanufacturing

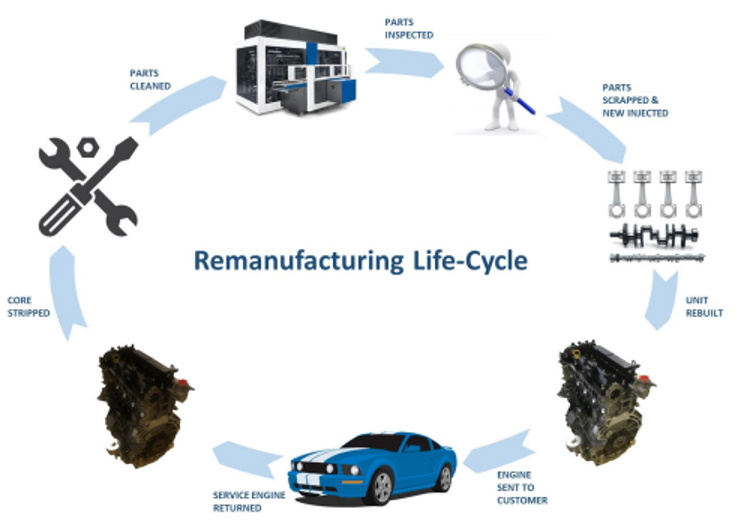

The Automotive remanufacturing business began around seventy years ago and proves to be the best way to put into practice what the circular economy is all about. When a component is damaged or at the end of its life, such as engine, transmission, or powertrain components, instead of eliminating it and buying a new component, thanks to the art of remanufacturing, used parts have a second life. The remanufactured components are the same as new or even better because companies incorporate all the engineering upgrades in the new components. There is no difference compared to the genuine parts and it takes 80% less energy to remanufacture a component compared to that used to produce a genuine one, saving up to 30% in costs.

The future of the remanufacturing

Vehicle longevity has gradually been increasing, and the average age of vehicles on the road is now over seven years. This should provide an opportunity for the remanufacturing sector as a whole as it is likely that more spare parts will be required. The EU’s End-of-Life Vehicle (ELV) legislation could buoy the remanufacturing industry in this sector. Historically, the automotive industry has demonstrated a high degree of reuse and recycling. Remanufacturers may be able to take advantage of this by providing alternative and superior reuse options for the industry.

From an environmental point of view, finally, products are salvaged through remanufacturing, and thus the materials and energy needed to produce products are saved to a large extent in comparison to other end-of-use options within the product life-cycle. One reason why remanufacturing is found attractive from an environmental point of view is that the efforts made when manufacturing new parts, e.g., material extraction, material manufacturing, part manufacturing, and product manufacturing, are fully or partly salvaged through remanufacturing.

So, there is no planet B. Being smart therefore means keeping the opportunity of mobility while keeping the planet alive. In one sentence, value for money and support for the environment by reducing the use of raw materials!