Christoph Dutschke is excited. The future is challenging and unpredictable but he isn’t bothered by that. As technical service Europe coordinator of training for Mahle Aftermarket, he sees only opportunities. But the trick to grasping them, he insists, is to be ready for what’s coming – even if you don’t quite know exactly what it is. “You need to be prepared, educated and you need to have the tooling for these different technologies,” he says. “From the workshops of today, only those will survive who are wearing running shoes: investing in new technology, new toolings, to be prepared for all repair jobs that will come.”

Dutschke has been with German group Mahle for 30 years. It specialises in engine systems and components, filtration and thermal management, covering off all aspects of powertrain and air conditioning technology. He started work with Mahle as a student and returned in 1992 after a degree in mechanical engineering at university to jump straight into sorting out warranty claims and developing technical training for customers. He is in good company: Mahle has nearly 80,000 employees worldwide – and 6,500 of them are mechanical engineers (“every 11th person,” he laughs).

Every second vehicle

This makes sense: many automotive original equipment manufacturers (OEMs) are not really ‘making’ cars anymore – at least not in the way that most people would understand the term. “No-one is taking the scissors and cutting out cylinder head gaskets,” he goes on. Instead, OEMs are increasingly turning to suppliers such as Mahle. The company positions itself as a specialist in drivetrain systems, “internal combustion engine (ICE) and everything around it”. OEMs might plan a launch in five years’ time and want elements such as filters, pistons and bearings for their new product; they would visit a company such as Mahle to explain what they want. “We’re not buying parts from China,” points out Dutschke. “We are a developer and manufacturer of these parts.”

The company says its products are “fitted in at least every second vehicle worldwide”. But into what sort of vehicles will these parts be put in future? And therefore what skills will the industry need? His keynote address to ReMaTec 2019’s audience will look at a broader issue and examine how things are changing for automotive: the 2016 Paris Agreement was signed by nearly 200 countries and pledged to keep global warming to under 2 degrees Celsius. “Relating to the global goal of climate change, the near future will be very exciting,” Dutschke says. “Everybody is working very hard to follow these targets and reduce CO2 emissions.”

The ICE is under threat, and alternative power sources, such as electric vehicles (EVs) and hybrids are gaining in popularity. So what will be the drivetrain of the future? “There are more and more alternative vehicles on the market, but the biggest share is vehicles with ICEs,” he continues. “Slowly, slowly, EVs et cetera are coming on to the road. But how will it be in 2030?” Put simply, figures suggest that penetration of alternative vehicles will be a maximum of 30% in the next decade. “So more than 70-80% will still be cars with ICE. My clear message to workshops is that ICEs will be on the road for many, many years,” Dutschke says firmly. “They need to be serviced and maintained for the next 10-15 years. On the other hand, more and more EVs are coming onto the road. So mechanics need to be educated for EVs as they are coming, piece by piece.”

Reducing emissions

Mahle knows all about the importance of adaptability. “Five to 10 years ago, Mahle was a specialist for ICEs,” Dutschke recalls. Then, in 2008, the company developed a new engine, just to get a feel for what was possible. It came up with a three-cylinder, 1.2 litre engine which had the same power as a six-cylinder, 2.4 litre engine. “The target was to reduce fuel consumption by 25%,” he explains. Other manufacturers, including Ford and Mercedes-Benz, have followed suit. “You get nice power and excellent fuel consumption, with low CO2 emissions.”

Given the drive systems available already, it is by no means clear what the future will hold. That is why Mahle has put in place what it calls the ‘dual strategy’. “If you ask three really good specialists what will be the future drive systems, you will get five different answers,” Dutschke says.

He says he prefers to discuss all the options: ICE, hybrid, EVs, battery electric vehicles (BEVs) and so on. “Electric cars – which I personally like very much – the number of gas stations is a problem. In Germany in 2017-18 we doubled the number from 20 to 40 – it’s nothing! It’s not enough: we will kill these cars. But it’s a really nice concept.”

In 2017, Mahle introduced MEET, a 48-volt concept vehicle, combining two electric motors, the transmission and a 48-volt electronics system, which the company said could do seven days’ worth of inner city trips on a single charge.

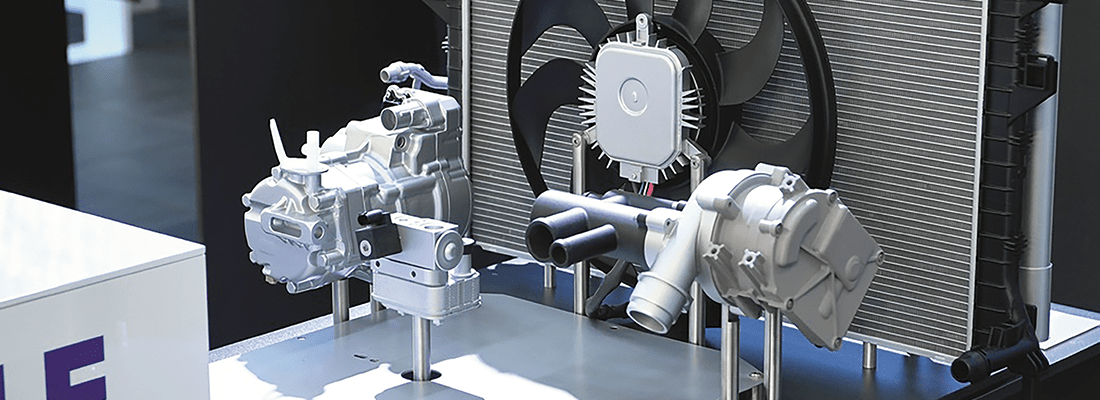

Thermo-management of hybrids and BEVs is a sophisticated job. “The electric motor is much more sensitive than the ICE when it comes to over-heating,” suggests Dutschke. “Thermo management is going to be much, much more important. The mechanic has to be trained.”

Looking ahead, he is enthusiastic about the changes that are surely coming to the aftermarket.

“We don’t want mechanics to be afraid of the future,” Dutschke concludes. “Should I have to close because of EVs? All mechanics worldwide are nervous about what will happen in the future. I want to cool them: be prepared – embrace new technology.”