There has been much discussion within the automotive repair industry about the differences between using OEM parts and the aftermarket equivalent repair parts. In this article, with a focus on turbochargers, we explore the benefits associated with using high quality repair parts and why such parts can actually improve a turbo repair.

The automotive aftermarket helps keep vehicles on the road by providing consumers with the choice of where they want their vehicles serviced or repaired. In today’s market, garages also have the choice between a wide range of turbo repair specialists.

What options are available?

As with many automotive components, it is likely that the original turbocharger will fail at some stage during the lifecycle of the vehicle. The options are; to repair or remanufacture the failed turbo with aftermarket components, replace the entire unit with a brand new OE turbocharger, or more so in today’s market, with an aftermarket equivalent complete unit. What is less obvious is a thorough understanding of the different options available.Where do you start to try and understand the ever increasing influx of repair parts suppliers? Should you choose OE over aftermarket equivalents, they are certainly more expensive but are they any better?

What is the difference between parts?

In today's crowded marketplace there are many aftermarket parts suppliers. Some specialise in specific parts, such as turbocharger parts, and others produce a wide range of general automotive components. More variety means more choice and a wider range of prices, but more importantly, varying levels of quality.

Aftermarket parts are generally less expensive than OEM parts; how much you save, however, varies by brand and also by the quality of the components. It is important to understand that there is a significant difference between top quality aftermarket parts and budget repair parts. Very low cost aftermarket parts are inferior and are often produced using lower-grade materials and less stable manufacturing processes, which results in unreliable parts.

It is important to understand the mentality of a low cost manufacturer, if you pay a very low price, you should expect to get a few bad parts in every hundred - that's why they are cheap! The only way to avoid this is to use high quality repair parts from a reputable manufacturer. What customers often don't realise is; a high quality aftermarket manufacturer does not just bring more competitively priced options over the OEM equivalent, they often bring added benefits and improvements over the original design, giving an improved product at a better price.

Part design improvements for better performance

Here we will provide some examples of cases where aftermarket parts have actually been improved over the OE equivalent, producing an improved aftermarket turbocharger.

Where an OE manufacturer will incorporate improvements into newer turbo designs, turbos that are entering the aftermarket at 4-5 years old will still incorporate the original design specification. Due to homologation, once a turbocharger design is approved by a vehicle manufacturer, the turbo OEM cannot deviate from this original approved design without seeking a revised approval which is very expensive for the vehicle manufacturer and not considered necessary. Aftermarket manufacturers are not restricted in this way.

Quality aftermarket manufacturers have the benefit of hindsight from analysing service failures in the market, and also the future knowledge of the latest developments in materials and manufacturing technology. Combining this knowledge with experience allows aftermarket manufacturers to correct inherent design issues, and also upgrade old turbo designs using new materials and improved component designs. The result is an improved aftermarket design over the original design.

Here are some examples of design improvements:

Thrust Flinger - Improved Twin Ring Design:

When the original KP35 turbo came out in the early 2000s, it was a flatback designed compressor wheel with one piston ring groove on the flinger. The original design was prone to oil leaks at the compressor end as the piston ring seal wasn't good enough. BorgWarner improved the design in later models by moving to a twin ring design, however the original turbos produced with a single piston ring remain, single ring, and have never changed. We now supply all our KP35 CHRA as standard with twin ring design.

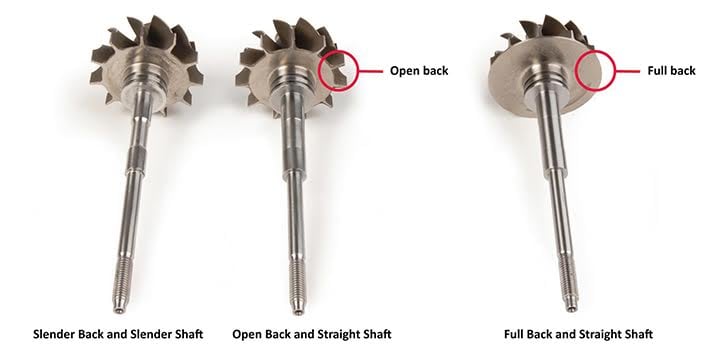

Increased Strength Casting - ‘full back face’ design

In recent years, there has been a general move towards a full back face turbine wheel casting design. This design gives a significantly stronger blade, preventing fatigue failure of the individual turbine blades. In applications where the casting failure is commonly seen, we have changed the shaft and wheel design to include a full back face casting. This reduces the chance of fatigue failure and generally gives a longer life in harsh applications.

Hot Forged vs OE Stamped Thrust Bearing:

The original K03/4 thrust bearings are produced using a stamped strip manufacturing process, which has limited strength. We produce the same part using the hot forged method, allowing use of a much superior high tensile silicon brass material which is common in most new applications.

Improved parts, like the above examples, will enhance the life of the repaired or remanufactured turbo. The result is a repaired turbo that performs better than the original unit fitted to the vehicle or the OE equivalent that is still identical to the original design due to homologation. OE parts are not always the highest quality option even though they are usually the highest price.

A key point to remember is that unlike OEM parts, not all aftermarket parts are produced equally and the quality of parts available varies depending on the type of manufacturer. Aftermarket parts can save you a lot of money, however with so many options available, it is essential that you make the right choice to provide your customers with a high quality turbocharger repair.

Share your remanufacturing stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the remanufacturing industry? The Rematec website and social media channels are a great platform to showcase your stories!

Please contact our Brand Marketing Manager.

Are you an Rematec exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.