People don’t often talk about ‘the art of remanufacturing’. While it’s true that there is something magical about manufacturing a product anew, remanufacturing people tend to be pretty practical. It is a dirty, complex business that doesn’t leave much time for standing and admiring. ‘Art’ is for other people – at least, that’s what you would think. More of that in a minute.

Down to earth

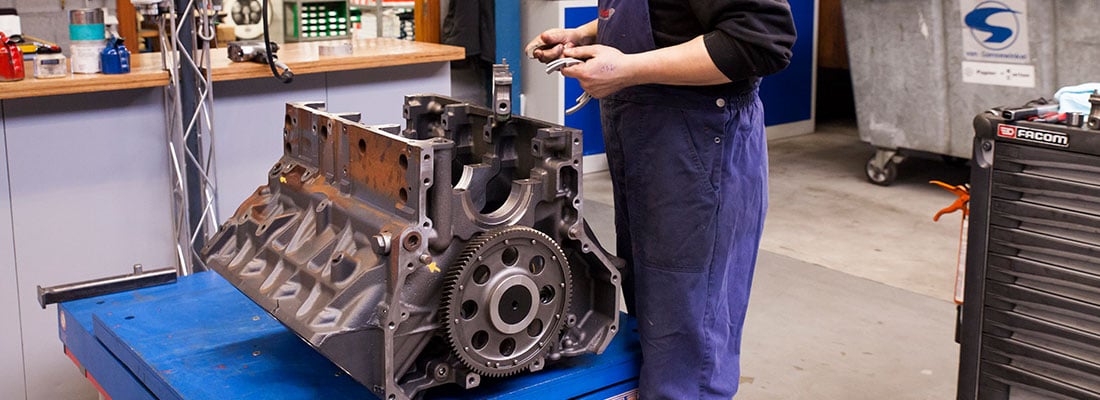

On the face of it, for Hamofa Industrial Engines, things could hardly be more down to earth. The company, based in Hamont, Belgium, has more than 40 years’ experience in working with diesel engines in some gritty sectors: public transport, railways, mining, construction, agriculture and energy. Its work is important in sectors where non-road machines can perform over a lifespan of 25 years. Specialising at the heavy industrial end of the market, with products such as cranes, the company also does some work in the automotive space looking after bus – rather than truck – engines. Hamofa also offers global delivery of new, remanufactured and used parts with warranties, has a stock of brand new engines and runs an exchange programme for customers. Like many outfits involved in the remanufacturing industry, it’s a family business – in this case run by Rob Verhoeven, his father, and two brothers. There is always a debate about what constitutes rebuilding and how it differs from remanufacturing. Verhoeven patiently explains: “My process is to rebuild an engine completely, so it is dismantled, cleaned and machined again to the original specifications, with new pistons, linings and so on. I’d say that’s remanufacturing – from zero to hero. My feeling is that you go from A-Z, which is as it should be: I test the engines to see if the pressure is as good, the temperature is good, and offer a 12-month warranty.”

The company is fiercely independent of any brand, Verhoeven tells ReMaTecNews. “We don’t want to be a dealer and we feel our customers value that. They want a company that does them all – so they are not having to go to Cummins, Caterpillar or Volvo separately. A machine that’s out of use is costing money.” In the 1980s Hamofa took its first stepsin the sector with smaller engines. In 1991 the company moved to its current site to work on bigger beasts and now has 10,000 sq m of workshops, offices and warehouses. In 2012 Hamofa made a major change-up, by extending its operations to the US. “Ten to 15 years ago, the European market was impacted by a lot of US brands, such as Caterpillar,” Verhoeven explains. “They did really well and customers would send them to us to repair, recondition and rebuild. We had to import parts which created delays and made things more expensive. Then we had a boom in European machines in the US, for example Liebherr cranes, which tend to be equipped with European engines such as Volvo, Deutz or Mercedes.” That meant the company got calls from US firms to ask if Hamofa could send them European parts. Rather than continue with this cross-Atlantic trade, the germ of an idea formed. Verhoeven investigated the US and found a machine shop in Fort Lauderdale, Florida, which had been owned by the same man for 50 years and seemed as though it might fit the bill. “I was interested because the machine shop had all the equipment, such as boring machines,” recalls Verhoeven. “Also, it was so big. I visited, talked to the owner – and bought everything: machine shop, building, customer list, employees.” The company sells rebuild engines in North and South America and Verhoeven says revenue has tripled since the Florida branch was opened. Attention to detail is crucial, he believes. “You can’t rebuild an engine cheap,” he says. “We take the complete package or we don’t do it.” Having got a firm foothold in the US and Europe, along with a presence in Russia, Verhoeven is turning his attention to other areas. “Probably the Middle East, maybe Dubai,” he muses. “We’re still thinking about what to do. We’re not standing still and saying we’re happy with what we do - but I want to keep my family business as a family business.”

The art of remanufacturing

Not only that, but Hamofa is happy to get involved in things which would be out of the ordinary to most companies in the sector – and this is where art comes into the story. Eric van Hove, a conceptual artist who works out of Marrakech, Morocco, approached Hamofa to take part in what must have seemed like a crazy – but wonderful – venture. This suggests the company is clearly happy thinking ‘outside the box’. And it is certainly not a small business, rising from six employees to around 60 in the last ten years or so. Whatever happens, Hamofa seems completely set on valuing its independence in future. “I never want to be related to any brand,” Verhoeven concludes. “What makes us strong is that we can sell whatever.”

Share your remanufacturing stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the remanufacturing industry? The Rematec website and social media channels are a great platform to showcase your stories!

Please contact our Brand Marketing Manager.

Are you an Rematec exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.