Turbocharger reman continues to face many challenges - but it is up to the market to take advantage of any opportunities and maintain quality standards, says Darren Johnson, Sales Manager of Melett.

The decline of diesel engines across Europe remains a concern. According to industry data expert GiPA, with the fuel type widely demonised, several countries saw diesel’s share of total registrations drop by 20% or more between 2014 and 2018.

But there are still millions of diesel cars between one and five years of age with their ‘prime’ workshop years ahead of them. With nearly half of the diesel parc falling into this category, GiPA fully expects the importance of diesel to the aftermarket to increase in the coming years, as more and more of these younger bracket vehicles age.

This, coupled with the growth in gasoline turbos does mean that, at the point of entry, turbos have a bright future.

Quality perceptions

It could be argued, however, that the main changes affecting the turbocharger market are further down the supply chain. With an expanding range, the emergence of new, lower cost units is affecting the perception of ‘new versus reman’ even more.

It is quite feasible for a reman turbocharger to be subject to greater scrutiny by independent garages than a new low-cost unit, despite the new unit potentially being of lesser quality than the remanufactured equivalent. This doesn’t just confine itself to turbochargers but to product groups such as rotating electrics and brake calipers, for example.

With this expanding range, the turbocharger market is also opening itself up to new distribution channels - but again this opens up more opportunities for the turbocharger specialist to support not only independent garages but also motor factors and warehouse distributors.

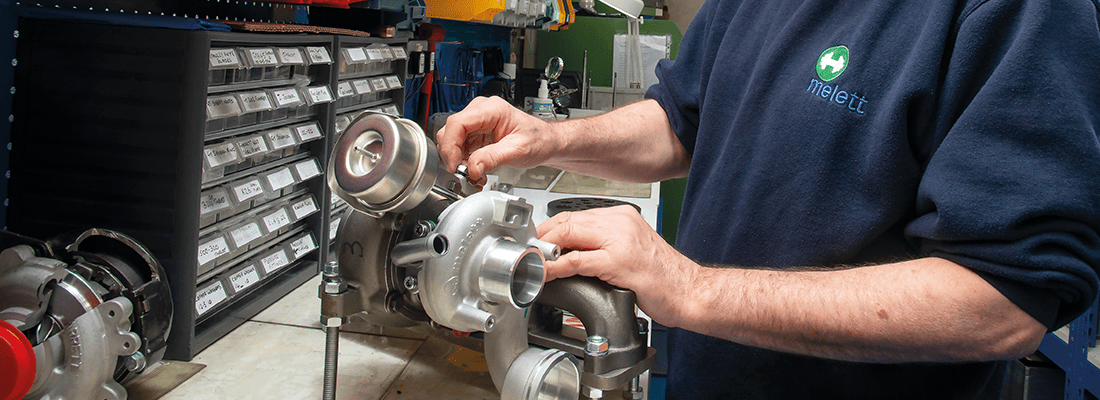

There is – and will always be – a reliance on businesses that have the specialist equipment and expertise to offer the very highest level of turbocharger repairs.

Reman standards

Melett, through its ‘What’s in Your Turbo?’ initiative, is encouraging the market to question parts quality even more and look beyond price and appearance. It is risky to assume that parts are identical, even if they look the same.

While components look very similar to their higher quality counterparts, component failure within days of operation is common as these poor quality products cannot perform efficiently under the extreme operating conditions. It is important to understand the point at which cutting margins turns into reducing quality. Every component has a minimal price point and anything lower than that point can only be achieved by using lower grade raw materials in the manufacturing process.

Due to the extreme operating conditions within a turbocharger, the level of precision required in the manufacturing of turbo parts is extremely high and consistency is vital. Producing one component with 100% accuracy is a relatively simple process; to achieve the same level of accuracy when producing thousands of components is an extremely difficult task, and without the use of strict manufacturing processes this would not be possible.

To produce quality on a large scale you need to use the correct materials, manufacturing processes and machinery combined with the correct quality systems, all of which are undertaken by companies such as Melett, adhering to internationally-recognised standards.

The fact remains, though, that the turbocharger repair market is at a pivotal point. It must fight this needless race to the bottom and promote remanufacturing, investment and engineering, leading to greater prosperity throughout the entire market.